是什么让运动激活电灯开关这样的自动设备与IoT 上做同样事情的设备有所不同?一句话:数据。在IoT 连接的设备上,当传感器检测到运动,执行器打开灯时,这些动作就会被捕获为数据,并发送到云端或数据中心进行记录和分析。有数据,就需要有

IoT 建筑学 它告诉数据去哪里、使用什么格式、如何到达目的地以及根据这些数据采取什么行动。

在这篇博文中,我们将简要介绍IoT 架构,并探讨它如何引导数据流进出设备和数据中心。

数据流:从边缘到服务器/云

IoT 系统架构通常被描述为一个四阶段过程,在这个过程中,数据从连接到 "物 "上的传感器流经网络,最终进入企业数据中心或云进行处理、分析和存储。

在物联网中,"物 "可以是机器、建筑物甚至是人。IoT 架构中的流程也会以指令或命令的形式向另一个方向发送数据,告诉执行器或其他物理连接设备采取某些行动来控制物理流程。执行器可以做一些简单的事情,比如打开一盏灯,或者在检测到即将发生故障时关闭一条装配线。

让我们一个阶段一个阶段地回顾一下这个IoT 架构。

第 1 阶段:传感器和执行器

这一过程始于传感器和执行器,它们是监测(传感器)或控制(执行器)某些 "事物 "或物理过程的连接设备。传感器捕捉有关过程状态或环境条件的数据,如温度、湿度、化学成分、储罐中的液位、管道中的流体流量、装配线的速度等。

这一过程始于传感器和执行器,它们是监测(传感器)或控制(执行器)某些 "事物 "或物理过程的连接设备。传感器捕捉有关过程状态或环境条件的数据,如温度、湿度、化学成分、储罐中的液位、管道中的流体流量、装配线的速度等。

在某些情况下,传感器可能会检测到需要立即做出反应的情况或事件,以便执行器能够实时执行补救措施,例如调整流体的流速或工业机器人的动作。在这种情况下,传感器与分析/触发执行器之间需要非常低的延迟。为了避免数据往返服务器、分析数据以确定故障和向 "物体 "发送控制信号的延迟,这一关键处理过程是在靠近被监控或控制的过程中进行的。这种 "边缘 "处理可由模块上的系统(SOM)设备执行,例如 Digi ConnectCore® 模块 和/或 带 Python 的 Digi 蜂窝路由器。

第 2 阶段:互联网网关和数据采集系统

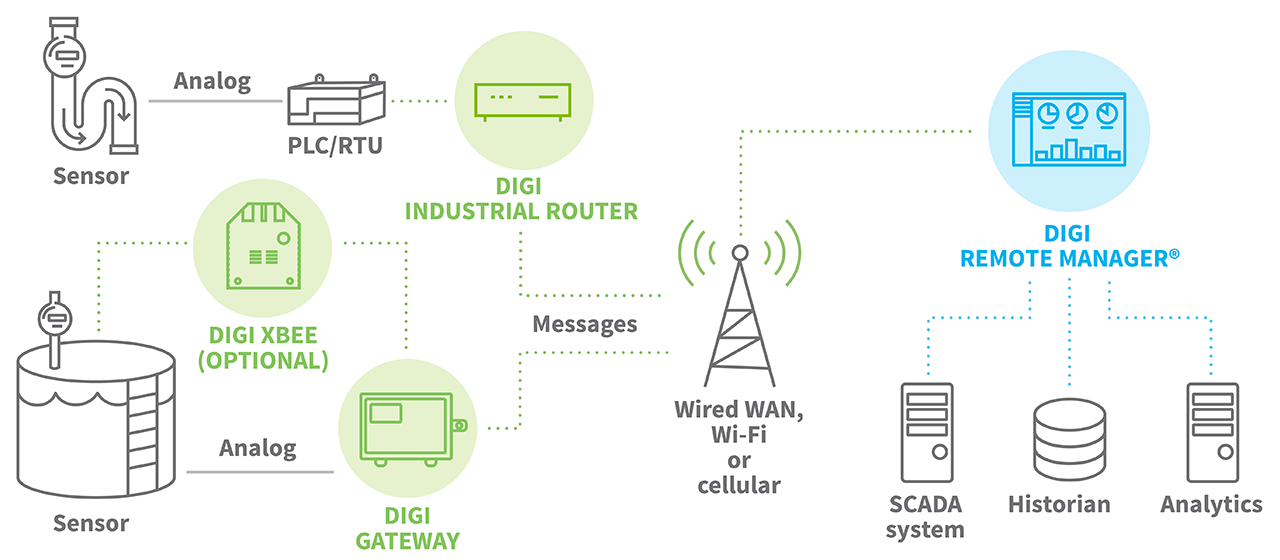

数据采集系统(DAS)收集来自传感器的原始数据,并将其从模拟格式转换为数字格式。然后,DAS 对数据进行汇总和格式化,然后通过无线广域网(如 Wi-Fi 或蜂窝网络)或有线广域网的互联网网关将数据发送到下一个处理阶段。

数据采集系统(DAS)收集来自传感器的原始数据,并将其从模拟格式转换为数字格式。然后,DAS 对数据进行汇总和格式化,然后通过无线广域网(如 Wi-Fi 或蜂窝网络)或有线广域网的互联网网关将数据发送到下一个处理阶段。

此时,数据量达到最大。数据量可能非常大,尤其是在工厂环境中,数百个传感器可能会同时收集数据。因此,数据也要经过过滤和压缩,以达到最佳的传输大小。

了解 Enlazza 如何使用 Digi RM 安全管理 Digi 路由器机群

"通过 HNS 连接到Digi Remote Manager ,我们解决了使用 IPv4 专用连接连接 Digi 路由器的问题"。

阅读故事

第 3 阶段:预处理:边缘分析

IoT 数据经过数字化和汇总后,需要进行处理,以进一步减少数据量,然后再传输到数据中心或云。作为预处理的一部分,边缘设备可能会进行一些分析。在这一阶段,机器学习可以为系统提供反馈,并持续改进流程,而无需等待企业数据中心或云传来指令。这种类型的处理通常在靠近传感器所在位置的设备上进行,例如现场配线柜。

IoT 数据经过数字化和汇总后,需要进行处理,以进一步减少数据量,然后再传输到数据中心或云。作为预处理的一部分,边缘设备可能会进行一些分析。在这一阶段,机器学习可以为系统提供反馈,并持续改进流程,而无需等待企业数据中心或云传来指令。这种类型的处理通常在靠近传感器所在位置的设备上进行,例如现场配线柜。

第 4 阶段:云或数据中心的深入分析

在流程的第 4 阶段,强大的 IT 系统可用于分析、管理和安全存储数据。这通常发生在企业数据中心或云端,在这里,来自多个现场站点/传感器的数据可以结合在一起,为整个IoT 系统提供更广阔的图景,并为 IT 和业务经理提供可操作的见解。一家公司可能在不同地区开展业务,IoT 数据进行分析,以确定主要趋势和模式,或发现异常情况。

在流程的第 4 阶段,强大的 IT 系统可用于分析、管理和安全存储数据。这通常发生在企业数据中心或云端,在这里,来自多个现场站点/传感器的数据可以结合在一起,为整个IoT 系统提供更广阔的图景,并为 IT 和业务经理提供可操作的见解。一家公司可能在不同地区开展业务,IoT 数据进行分析,以确定主要趋势和模式,或发现异常情况。

在这一层面,特定行业和/或特定公司的应用程序可用于执行深入分析,并应用业务规则来确定是否需要采取行动。输入的数据可能会显示设备设置的理想变化或优化流程的其他方法,从而形成一个有利于不断改进的循环。第四阶段还包括将数据存储在数据仓库中,以便保存记录和进行进一步分析。

流程需要平台

除了四级IoT 架构外,还必须考虑IoT 平台,该平台提供各级之间的连接。平台结构定义了数据流量的具体细节。它决定了数据的去向以及每个阶段的处理量。IoT 平台可根据系统的专业化程度进行或多或少的定制。

例如,IoT ,世界上任何一个城市的路灯都可能非常相似,而用于制造医疗设备的 3-D 打印机上的传感器和执行器可能是独一无二的。

进一步了解IoT 管理

凭借稳固的平台和精心设计的架构,IoT 可以提高几乎所有行业的安全性、效率和生产力。正确的IoT 平台可以为您提供成功所需的工具。

要了解IoT 平台的注意事项以及如何构建自己的IoT 架构,请观看我们的视频: IoT 平台的五大要求。

Digi Remote Manager®是一种安全、先进的IoT 设备管理解决方案,它为您提供了一个指挥中心来配置、部署、监控和管理您的IoT 项目。了解更多信息,请参阅我们的博文:什么是IoT 设备管理?

IoT最好的还在后面

虽然IoT 已在众多消费、商业、工业和基础设施应用中得到使用,但我们可以预见,在不久的将来,IoT 系统将以更大的数量和更多的应用案例出现。

正在规划您的IoT 项目?联系我们,开始对话。

下一步工作