What is the Industrial IoT, or IIoT? The Industrial Internet of Things is the use of connected smart devices in industrial applications for purposes such as automation, remote monitoring and predictive maintenance. The IIoT is a more robust version of the Internet of Things, or IoT, which is the realm of connected devices in commercial and consumer applications.

In Industrial IoT use cases, smart devices may be deployed in construction vehicles, supply chain robotics, solar and wind power, agricultural sensor systems, smart irrigation, and more. These IIoT applications tend to have one thing in common: they are are deployed in challenging environments, requiring the most robust sensors and devices.

There are light industry IIoT use cases such as meters, and heavy industry use cases such as conveyors used in the mining industry, where devices can be subject to a wide range of environmental factors, from extreme heat and cold to moisture and vibration. And in Industry 4.0, processes such as manufacturing automation and predictive maintenance require rapid machine-to-machine communications for precision and control of robots, equipment and processes.

The Industrial Internet of Things is about deploying sensors and smart machines to capture and move data, sense changes in temperature, flow or volume, automate procedures for efficiency, accuracy and safety, deliver data into the right hands for analysis and decision making, and ensure that all of those processes happen on time, reliably and securely.

The Power of Edge Processing and Automation in the Industrial IoT

The use of smart devices has rapidly expanded, and today — with the enormous growth of the IoT and IIoT, it’s hard to find an industry that is untouched by this phenomenon. Today, industrial organizations are seeking to work smarter, not harder. Fast networks, edge computing and automation can create unprecedented improvements and efficiencies that simply aren’t possible with a human workforce. This is not to say that humans aren’t necessary. On the contrary, engineers, application developers, data scientists and workers from every walk of life are needed to put these solutions in place and make use of them.

获取我们的解决方案简介

Learn how edge computing solves networking challenges

下载 PDF

Edge Computing for Rapid Data Processing

Edge computing processes data at the network edge, before transmitting data to the cloud, which provides cost benefits, and real time response. By integrating edge processing into the industrial IoT ecosystem, network managers can dramatically increase operational efficiency. In Industry 4.0 applications, this critical functionality paired with 5G network speed and throughput enables the real-time data transfer required for the most data-intensive applications such as manufacturing automation and robotics.

Even in traditional industrial processes, edge computing is a game changer, enabling real-time insights on remote operations, as well as key benefits such as predictive maintenance, which alerts technicians when certain conditions suggest impending failure. This ensures industrial outfits can proactively respond, often before a failure occurs.

Automation for Efficiency and Safety

Today, remote devices provide sensing, data insights and automation capabilities that launch industrial processes, and ensure remote machinery is operating normally. Automation provides an enormous range of benefits.

举个简单的例子,农场工人以前需要从农场的一个偏远角落开车到另一个偏远角落,以确保浇灌系统或防冻风扇在正确的时间打开。如今,这名工人可以通过笔记本电脑检查系统,确保一切工作正常,而且只需前往实际需要维修的地点。例如,如果中心枢轴灌溉系统偏离了轨道,工人可以使用全球定位系统快速确定其位置,然后确保其回到正确的位置。换句话说,工业物联网就是要提高效率和准确性,同时降低成本。

The impact of the IIoT on workers and jobs is that it makes them more efficient and improves productivity. It also reduces “busy work” and the likelihood of errors in tasks such as data logging, that are better handled by a smart device. Automated sensing and data gathering from dangerous and difficult-to-reach places even reduces risk to human lives. And it gets the right data to the right place for evaluation sooner. When an employee can get a smart phone alert that a tank is low or a piece of equipment needs maintenance, that improves the likelihood that problems can be solved early, before they become more expensive or catastrophic.

工业IoT 使用案例举例

了解商业和工业企业如何使用IoT 的最佳途径之一是通过众多 IIoT 应用实例。让我们来浏览其中的几个。

制造自动化

Industry 4.0 use cases, including manufacturing automation, or "smart manufacturing," have long been a forward-thinking vision that would one day combine the fastest networks and the most intelligent edge devices with cameras, sensors, AI and machine learning, as well as advanced robotics, to automate processes across the manufacturing chain from assembly and anomaly detection to packing and shipping. These visions are coming to fruition today, with the wider availability of high-speed 5G networks, the rollout of 5G edge computing devices, and the maturing of advanced technologies like AI. Today, these innovations and developments are all coming together to bring the vision of Industry 4.0 to life.

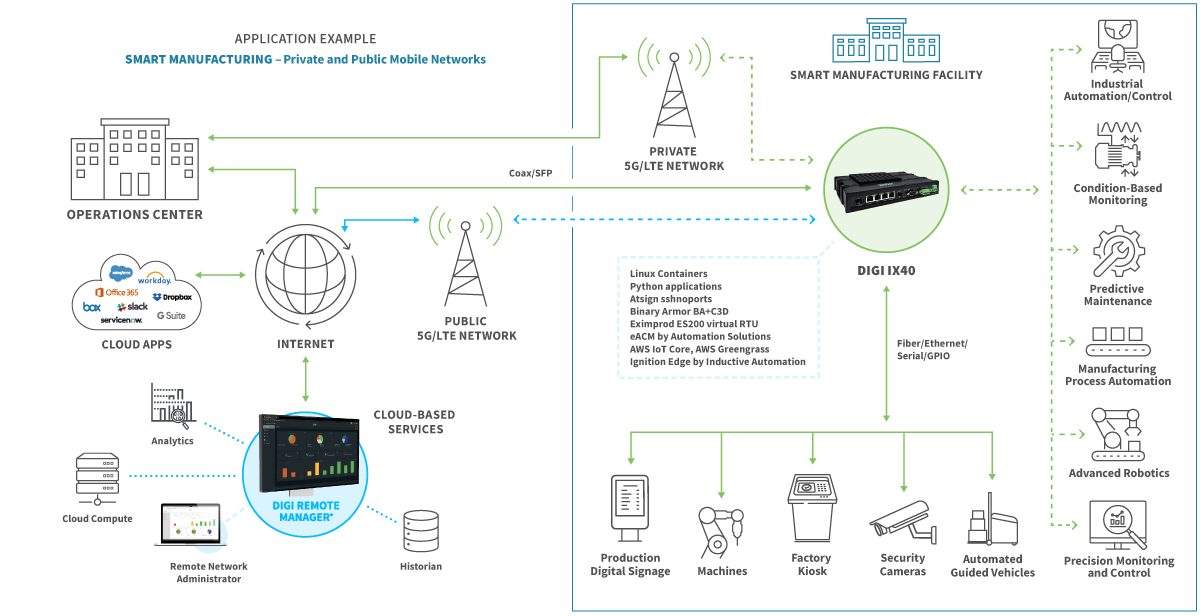

The following diagram shows smart manufacturing in practice.

预测性维护

Predictive maintenance applications seek to identify when a critical business process or piece of equipment is at risk of failure, so proactive and preventive maintenance can be scheduled to fix problems in advance and thwart downtime. Traditional methods can be very expensive and workers can inadvertently miss indicators that equipment is experiencing problems. In many cases, technicians and maintenance workers have traditionally had to travel to remote sites to perform manual checks, only to have to make another trip with a work order, replacement parts or batteries. Getting an alert that a problem is developing makes it possible to troubleshoot and fix an issue with one truck roll, often before the end customer is even aware of the problem. The result is improved maintenance practices, reduced costs and enhanced customer satisfaction.

以下是各行业 IIoT 预测性维护应用的几个实例。

- Process monitoring — mining: In the classic game “Rock, Paper, Scissors” rock can be beaten by paper. However, in the real world, rock beats everything. In mining applications, large conveyor belts transport earth (lots of rocks) from one area to another over long distances, over a mile in some cases, where the material is processed to extract valuable minerals. If the conveyor belt and supporting equipment “go down” or stop, it can cost a mine millions of dollars in lost revenue. To ensure the conveyors work without interruption, 24/7, sensors are added to the conveyor to gather data points and send that data via a radio device (e.g. Digi XBee®) to a gateway and then to a remote monitoring application. Digi Remote Manager® can help monitor those gateways and devices at different mines and quarries to prevent undesired down time.

- Equipment maintenance — elevators: The OTIS elevator company wants to ensure that the customers who install their product receive the highest quality service. Rather than wait until a problem occurs that impacts daily operations and customer satisfaction, the company puts sensors in place, in hundreds of thousands of installed elevators. These sensors communicate data points through a gateway to a cloud environment that provides insights and automated notifications to field technicians.

- Asset monitoring — construction: An energy management company provides solutions to customers such as construction companies. They develop a range of IoT tools to help these organizations ensure they are optimizing vehicle use and identifying problems before they result in lost revenue. To predict hydraulic hose failure before it results in equipment breakdown, expensive hydraulic fluid cleanup and potentially injuries, the company develops a connected solution that monitors equipment, identifies and reports on data points that indicate a potential failure, and enables customers to set up alert conditions and receive automated notifications.

Predictive Maintenance Application Example

In the following example, a Digi XBee® radio module collects data from equipment in a grain elevator and sends it to a Digi IX40 industrial router, which then delivers that data to cloud-based applications for visibility and further processing. If the data indicate certain conditions, a technician can see that in online application, or receive alerts from an application such as Digi Remote Manager®. The technician can workthrough a troubleshooting process remotely or send personnel to the site to perform the required maintenance.

远程监控

Remote monitoring is at the center of many industrial applications, because it is traditionally inefficient, expensive and often challenging or risky to keep tabs on what is happening with equipment out in the field. Equipment that requires monitoring can be located at remote outposts, on the top of street lighting, inside a well or deep in a mine, making it not only impractical to manually monitor that asset, but also expensive and risky.

以下是工业应用中远程监控的许多例子。

- Tank monitoring — oil and gas: Throwing rocks at a tank or using a stick to tap a tank to determine fluid levels have been common practices in the past that can be dramatically improved with IIoT applications. Tanks at production oil wells need to be monitored to ensure there is no overflow, which can result in hefty fines and cleanup costs. Monitoring onsite tanks with chemicals that are injected downhole to reduce pipeline corrosion are also an important part of daily operations. To reduce risk and optimize efficiencies, a company can install an automated tank monitoring solution that sends level readings as needed (such as by the minute, hourly or daily) to allow field managers to manage pickups or deliveries as well as preventive maintenance calls based on actual data and level readings. Taking this step also prevents the cost of sending personnel to each of the tanks on a rotation schedule, regardless of the tank levels. Instead they only send personnel when needed.

- Flow monitoring — agriculture: Center pivots in agriculture are a common way to distribute water across crop fields. Water goes through a pipe and is distributed through sprinklers as the center pivot moves slowly in a circle. A leak in a center pivot or any other irrigation line can cause major damage and cost thousands of dollars in repairs and lost resources. Remote monitoring of pressure and movement can help proactively identify issues on a irrigation pipeline. Plugged heads, leaks or even disconnected fittings can be sensed early and alarms sent to help farmers avoid issues, maintain crop growth, and limit capital spent on fixing problems.

- Chemical process monitoring — refineries: Remote management doesn’t have to be 100 miles. In many cases it may only be 100 feet, or a football field away. Monitoring at processing facilities has traditionally been done with wireline installations. One challenge is that cables are expensive to install and maintain. Another challenge is that wired systems can be subject to corrosive environments and other factors such as earthquakes and catastrophic weather events. A processing plant might have hundreds or thousands of sensors in place to gather data, for example to monitor a chemical batch, make sure it is under control and avoid spillage or explosions. Today, businesses such as these are turning to the Industrial Internet of Things to further monitor and automate processes, such as taking readings and recording them in a cloud-based system for analysis, reporting and alerts that can be accessed from mobile devices.

使用 1844myfuels 对油罐进行无线监控

"Digi已经成为我们整个解决方案的一部分。这是第一款真正意义上的无线产品,占地面积小,而且还能正常工作"。

阅读故事

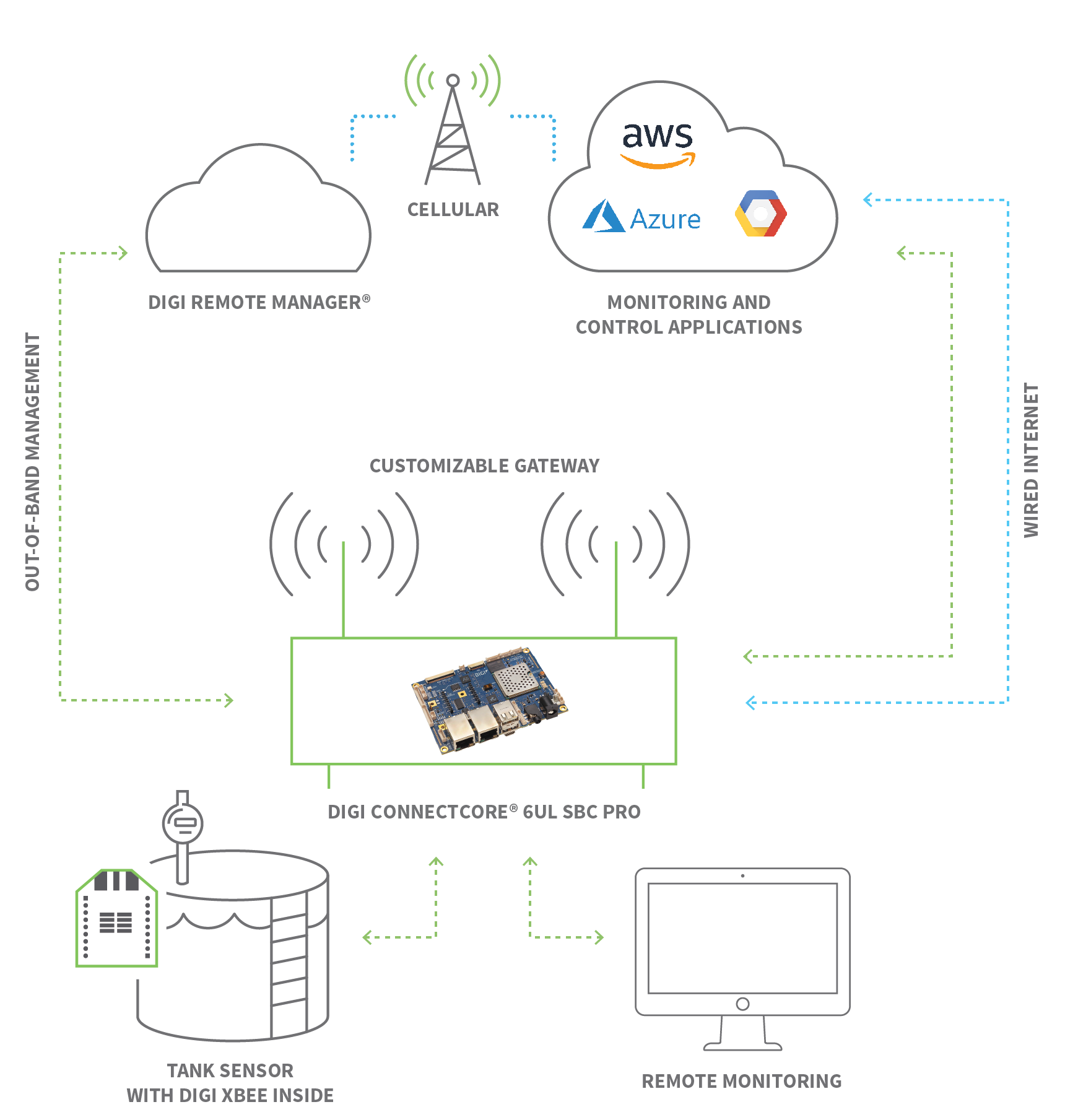

远程监控应用示例

在这个远程监控示例中,无线电模块从工业储罐收集数据,并通过嵌入式处理器将数据传输到云端应用程序,以进行监控、警报和调整。

过程自动化

在工业领域部署互联应用的另一个常见原因是将原本需要人工干预、卡车翻滚或低效手工劳动的流程自动化。使用案例的范围很广,但将这些工业物联网流程部署到位的原因还是归结为几个关键驱动因素:提高效率、降低成本和减少风险。

以下是 IIoT 自动化的几个例子。

- Smart Irrigation — The good old days of watering on a schedule just because you have water are slowly evaporating (pun intended). Today, farmers are adopting technology to monitor soil conditions and weather, among other factors, to determine when and where water is needed. Soil moisture sensors connected to wireless modules that relay sensor data to gateways and then the cloud allow farmers to monitor growing conditions. And automating the watering process based on moisture readings ensures water resources are used efficiently — where, when and for how long that watering is needed.

- Automatic modification — The energy sector today is turning toward automation to modify equipment behaviors based on conditions. For example, the wind often cools things down on a hot summer day. But too much wind can cause havoc in all sorts of environments, such as agriculture, wind mills and solar installations. When strong winds kick up in a solar field, weather stations can monitor when wind speeds can reach damaging thresholds. Wireless communication from a gateway can send commands to solar panels to move to a safety position that can help reduce or avoid damaging these high-cost assets.

- Frost fans — There’s nothing like an early frost to ruin your year-end harvest. Likewise a late frost in the spring might damage plants that are ready to bloom. Wireless sensor technology combined with giant fans on high value crops in orchards and vineyards allow farmers to monitor weather conditions so they can turn on fans to limit damage from early/late frost. It is a bit like having a heating and air conditioning system for your crops. However, these fans traditionally need to be manually turned on as unexpected frost temperatures arrive. This means farmers must make the rounds to each of the points where they have installed fans around their acreage, often in the middle of the night. An application that automates these processes can not only sense when temperatures are heading toward the frost range, but also trigger a process to start the fans. Meanwhile, the farmer can rest easy at night, and can see at a glance from a mobile device which fans have been turned on and if they are functioning properly.

过程自动化应用实例

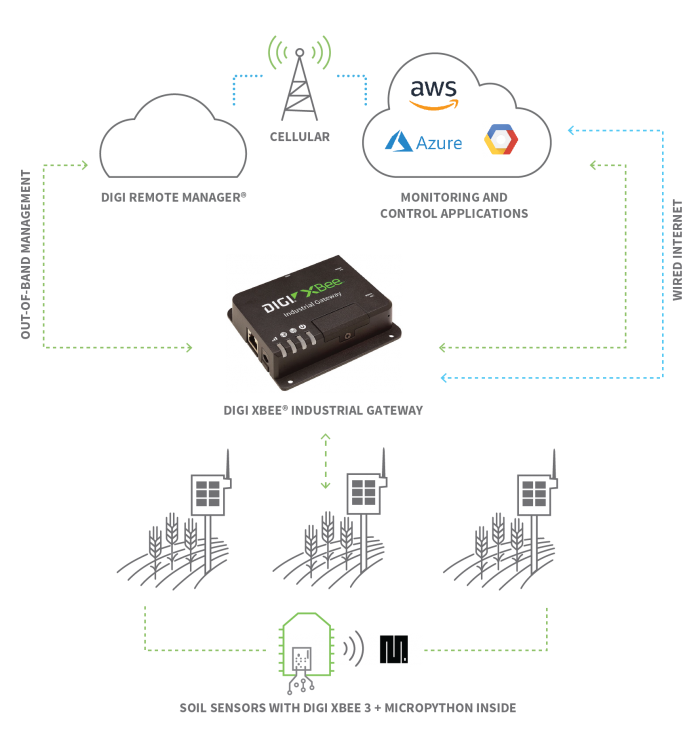

在下面的流程自动化示例中,土壤传感器收集数据,通过Digi XBee 模块与 MicroPython 将数据传输到Digi XBee 工业网关,然后再传输到基于云的远程监控应用程序。其中一个应用程序可自动启动进程,而另一个应用程序则允许网络管理员或管理员确保所有设备和进程按预期运行。

工业IoT 应用的重要考虑因素

在为您的工业IoT 应用评估合适的设备和设置时,需要考虑很多问题。其中包括 IIoT 设备需要传输数据的距离、数据提交的频率、射频或蜂窝技术是否适合您的应用,以及影响项目整体规划、部署、可扩展性和管理并最终影响总拥有成本的许多其他决策。

我们将介绍在您准备设计、构建和部署项目时需要考虑的一些事项。如果您有疑问或准备评估解决方案,Digi 团队成员可以与您合作,对您的应用需求进行全面评估。Digi 设计和工程团队还可在开发 IIoT 应用程序的过程中提供任何级别的支持。联系我们,开始对话。

工业设备与原型制作工具:

A critical step for Industrial IoT applications — and in fact any professional product that will face environmental challenges such as fluctuating temperatures or vibration — is to find the right product for the job. If you develop a product for an application such as a city bicycle ride share service, for example, the application may not technically be considered an industrial application, but its requirements are similar as it will need to be able to handle jarring movement, temperature changes and moisture. Some types of devices can handle challenging environmental factors, and some are less suitable. So it is critical to evaluate the robustness of a product and whether it is designed for the intended application.

There are many low-cost modules that are excellent for rapid prototyping and for student projects, such as Raspberry Pi and Arduino. The attractive cost is a good reason to use these products in initial phases. But you will want an industrial-rated product designed for long-term viability in demanding environments when seeking products that are suitable for IIoT applications.

Some of the factors to evaluate in a product include:

- 生产质量控制

- 产品的长期可用性和稳定性

- 测试温度范围

- 设计灵活性和可编程性

- 支持工具和代码库的可用性

- 能够主动更新固件,尤其是当部署规模超过几台设备时

- 应用程序部署地区的认证。

从原型开发工具开始是证明概念的好方法;但当您准备在现场部署设备时,一定要选择工业级设备。

远程管理战略

Traditional maintenance methods of sending a truck out to the field to monitor or manage equipment quickly become impractical and costly when you have dozens, or hundreds, or even thousands of devices to maintain. Just like your cell phone, which has firmware upgrades that are pushed out regularly, devices have firmware updates and security patches that must be sent to each of the devices in your IIoT network to keep those devices up-to-date and secure. A remote management solution allows you to send bug fixes and feature enhancements to all of your devices in the field, regardless of the size of your network.

To implement a remote management strategy, look for a solution that will enable you to perform remote firmware upgrades, device connectivity, and remote diagnostics from anywhere, using a smart device. For example, Digi Remote Manager is a cloud-based solution that provides these capabilities and more, enabling you to set alerts for a range of conditions, download files, and automatically monitor device configurations and reset them to the correct version in the event of tampering.

与派一辆铲车对安装在路牌或路灯上的设备进行固件升级的成本相比,安装远程管理系统非常经济,而且无论网络中有多少设备,也无论这些设备位于世界何处,网络管理员都能对所有设备进行监控。

结论

The evaluation and decision making that go into the development and deployment of an IIoT application can be daunting. Digi can support your quest to identify the right solution for your needs at any point along the way, from initial project scoping to complete engineering and certification services.

Whether you want to demonstrate the ROI of a new product or need to meet a strict deadline for compliance or market pressures, Digi can partner with you to achieve those goals. Time to market can be especially critical when there is a short-lived window of opportunity to get ahead of competition.

Working with a company that has proven professional consulting and engineering support not only gives you the assurance that you can meet deadlines and launch dates, but also helps you complete design reviews and get certification assistance when your resources stretched thin.

下一步工作